Anyone ever make your own motor mounts?

Registered User

Thread Starter

Join Date: Apr 2005

Posts: 2,162

Likes: 0

Received 0 Likes

on

0 Posts

I was looking to buy some new mounts for the s14...I was about to get the Circuit Sports kit...

But then I thought, wow, they're really just cylinders with a bolt through the middle. Ok, time to make some instead. lol.

Here is the specs of some raw material I think would work. Does anyone know a good place to buy polyurethane rod like this from? Local would be a huge plus...

Material Type--- Polyurethane

Shape---Rods

Backing--- No Backing

Length--- 6"

Length--- Tolerance ±1/4"

Diameter--- 2"

Diameter--- Tolerance +0.020",-0.010"

Durometer--- Hard

Durometer Rating--- 80A

Durometer Hardness Tolerance--- ±5

Temperature Range--- -20° to +185° F

Tensile Strength--- 6500 psi

Color--- Amber

Finish--- Smooth

Tolerance--- Standard

Specifications Met--- Not Rated

Properties--- Oil Resistant, Abrasion Resistant, Tear Resistant, Impact Resistant, Weather Resistant, Chemical Resistant, Electrical Resistant

Notes--- Color varies from translucent to opaque.

...only thing Im thinking is I need to find something with a better temperature rating..

But yeah basically Id just get a piece of rod, cut it down to just over 2 inches long, and drill a hole through for a bolt. Add a couple washers and nuts, BAM, custom motormounts in whatever height/durometer you want them for under $50.

Alternatively, I can order some pourable poly mix, and just make some molds for them. I almost think that would be easier than drilling holes in premade poly because I can just stick a sleeve in the mix before it dries.

Here is some ShoreA-80 durometer pourable stuff I found...I would think the trial size would be plenty....unless anyone wants to buy a set when I finish em =P

http://www.smooth-on.com/Urethane-Ru...tml?catdepth=1

Another possibility with the pour-able type is that I could make a true "isolator" mount ... aka instead of some all-thread running right up the middle there could be two studs, one on each side, anchored into the poly.

Thoughts?

But then I thought, wow, they're really just cylinders with a bolt through the middle. Ok, time to make some instead. lol.

Here is the specs of some raw material I think would work. Does anyone know a good place to buy polyurethane rod like this from? Local would be a huge plus...

Material Type--- Polyurethane

Shape---Rods

Backing--- No Backing

Length--- 6"

Length--- Tolerance ±1/4"

Diameter--- 2"

Diameter--- Tolerance +0.020",-0.010"

Durometer--- Hard

Durometer Rating--- 80A

Durometer Hardness Tolerance--- ±5

Temperature Range--- -20° to +185° F

Tensile Strength--- 6500 psi

Color--- Amber

Finish--- Smooth

Tolerance--- Standard

Specifications Met--- Not Rated

Properties--- Oil Resistant, Abrasion Resistant, Tear Resistant, Impact Resistant, Weather Resistant, Chemical Resistant, Electrical Resistant

Notes--- Color varies from translucent to opaque.

...only thing Im thinking is I need to find something with a better temperature rating..

But yeah basically Id just get a piece of rod, cut it down to just over 2 inches long, and drill a hole through for a bolt. Add a couple washers and nuts, BAM, custom motormounts in whatever height/durometer you want them for under $50.

Alternatively, I can order some pourable poly mix, and just make some molds for them. I almost think that would be easier than drilling holes in premade poly because I can just stick a sleeve in the mix before it dries.

Here is some ShoreA-80 durometer pourable stuff I found...I would think the trial size would be plenty....unless anyone wants to buy a set when I finish em =P

http://www.smooth-on.com/Urethane-Ru...tml?catdepth=1

Another possibility with the pour-able type is that I could make a true "isolator" mount ... aka instead of some all-thread running right up the middle there could be two studs, one on each side, anchored into the poly.

Thoughts?

__________________

Last edited by omgosh; 06-21-2011 at 11:08 PM.

Well, would you trust your handwork on a very delicate piece of equipment that is designed to keep your car's engine in the proper position to avoid wear, shake, abnormal idle and transmisison wear?

but hell peple just run bolts through hockey pucks and it seems to work fine.

BUTTT at the same time..

but hell peple just run bolts through hockey pucks and it seems to work fine.

BUTTT at the same time..

__________________

Registered User

Thread Starter

Join Date: Apr 2005

Posts: 2,162

Likes: 0

Received 0 Likes

on

0 Posts

LOL nice post.

To answer that question, sure I would. Its not like I went out to Walmart at 3am and bought a 4-pack of pucks (Do they even come in packs? Or would Wally World even stock 4 pucks in Florida?) Instead Im up late researching polyurethane online lol.

So yeah, Id like to think I can do a bit better than ^that^ guy who probably used "grade 5" bolts from ACE.... and that asshole on NICO who used SOLO cups for his molds.

To answer that question, sure I would. Its not like I went out to Walmart at 3am and bought a 4-pack of pucks (Do they even come in packs? Or would Wally World even stock 4 pucks in Florida?) Instead Im up late researching polyurethane online lol.

So yeah, Id like to think I can do a bit better than ^that^ guy who probably used "grade 5" bolts from ACE.... and that asshole on NICO who used SOLO cups for his molds.

__________________

Wow, Hockey pucks is definitely not a solution I saw coming. Making the actual shapes of the mounts is very easy, But compressing them to what they have them has to be a little difficult. How much are the circuit's?

__________________

1995 Emerald blue S14 (DAILY)

1996 Emerald blue S14 (Weekend car)

1995 Champagne S14 (trailer)

1993 black s13 convertible (beach cruiser)

1995 Emerald blue S14 (DAILY)

1996 Emerald blue S14 (Weekend car)

1995 Champagne S14 (trailer)

1993 black s13 convertible (beach cruiser)

LOL nice post.

To answer that question, sure I would. Its not like I went out to Walmart at 3am and bought a 4-pack of pucks (Do they even come in packs? Or would Wally World even stock 4 pucks in Florida?) Instead Im up late researching polyurethane online lol.

So yeah, Id like to think I can do a bit better than ^that^ guy who probably used "grade 5" bolts from ACE.... and that asshole on NICO who used SOLO cups for his molds.

To answer that question, sure I would. Its not like I went out to Walmart at 3am and bought a 4-pack of pucks (Do they even come in packs? Or would Wally World even stock 4 pucks in Florida?) Instead Im up late researching polyurethane online lol.

So yeah, Id like to think I can do a bit better than ^that^ guy who probably used "grade 5" bolts from ACE.... and that asshole on NICO who used SOLO cups for his molds.

Seriously though, I don't even know why. OEM is good and its cheap as hell. Just buy it premade, do you really want to try to save 20$ in return of possible engine/transmission damage? If your custom idea fails crusing at 55mph, it will WRECK your mechanical and will be a safety issue to you, and everyone else around you.

Just imagine, you die because you wanted to save a few bucks. Not the first person to do it, granted but hell you aren't going to be the last.

__________________

I am sure Circuit Sports and EVERY other maker of engine mounts went through some sort of R&D, trials in a controlled environment and other testing for strength and stamina testing. Im thinking pouring engine mounts is a bad idea.

__________________

plenty of people drive around on totally torn apart engine mounts and many never know it.

my dumb drifter friend had both mounts totally torn apart. you could see the engine rock when kicked it.

The thing is, the bolt in the stock mount isn't exactly straight, so what happens, is when you shove a bolt straight though, it gets torqued around pretty good and ends up snapping and that's what falls apart, the pucks vibrate out and now the engine is tilted over on its side.

What you "could" do, as it has been done time and time and time before, and again, is go to home depot, get a tube of the polyurethane construction adhesive, some rubber gloves and a couple of bad stock mounts and either cover the whole thing with the stuff and let it dry, or, get really crazy and do on half of it, let it dry. so that it will hold its shape, then cut out the stock rubber, put in more goo, let it dry and just do a little bit at a time until you've made a solid mount. Then just shave away what you don't want/need. re-shape the whole thing to the way you want it. It'll work for a while and be nice and stiff that way. Typically, they end up tearing apart from a crappy bond between the metal and the poly when you pull the engine out, so that might be a hurdle to overcome.

From a liability standpoint, they have to test their mounts, but it is the same poly you can get, and it is poured into a mold. They have a system of some sort to ensure no air pockets and good bonds and all of that.

Oh, and another major problem people have doing the whole puck thing is that they make the engine sit lower since two pucks isn't as thick as the stock mount. A lower engine means the oil pan catches on more shit. That's what looks like what might have happened with that car in that pic considering the engine was still sitting up right.

It would have to be a pretty serious situation to really jack crap up if the mounts fail. All three, (including the tranny) would have to fail for the engine to "fall out" or spin around or anything like that.

So while there is some risk, it is a rather acceptable amount of risk to test you ideas on.

You'll know when it starts to go bad long before it is totally fucked.

my dumb drifter friend had both mounts totally torn apart. you could see the engine rock when kicked it.

The thing is, the bolt in the stock mount isn't exactly straight, so what happens, is when you shove a bolt straight though, it gets torqued around pretty good and ends up snapping and that's what falls apart, the pucks vibrate out and now the engine is tilted over on its side.

What you "could" do, as it has been done time and time and time before, and again, is go to home depot, get a tube of the polyurethane construction adhesive, some rubber gloves and a couple of bad stock mounts and either cover the whole thing with the stuff and let it dry, or, get really crazy and do on half of it, let it dry. so that it will hold its shape, then cut out the stock rubber, put in more goo, let it dry and just do a little bit at a time until you've made a solid mount. Then just shave away what you don't want/need. re-shape the whole thing to the way you want it. It'll work for a while and be nice and stiff that way. Typically, they end up tearing apart from a crappy bond between the metal and the poly when you pull the engine out, so that might be a hurdle to overcome.

From a liability standpoint, they have to test their mounts, but it is the same poly you can get, and it is poured into a mold. They have a system of some sort to ensure no air pockets and good bonds and all of that.

Oh, and another major problem people have doing the whole puck thing is that they make the engine sit lower since two pucks isn't as thick as the stock mount. A lower engine means the oil pan catches on more shit. That's what looks like what might have happened with that car in that pic considering the engine was still sitting up right.

It would have to be a pretty serious situation to really jack crap up if the mounts fail. All three, (including the tranny) would have to fail for the engine to "fall out" or spin around or anything like that.

So while there is some risk, it is a rather acceptable amount of risk to test you ideas on.

You'll know when it starts to go bad long before it is totally fucked.

I ran JGS tools semi solid urethane mounts on my car for two years. They were SUPER stiff, I actually didn't have too bad of an experience with them because my old car wasn't the typical rattly piece of shit 240sx that's become all too familiar these days.

There's a few BMW shops that are becoming known for making poly mounts with bad batches of polyurethane that rip apart... UUC Motorworks for example. I would be worried that if they can't make it correctly or get it to last very long, neither could you.

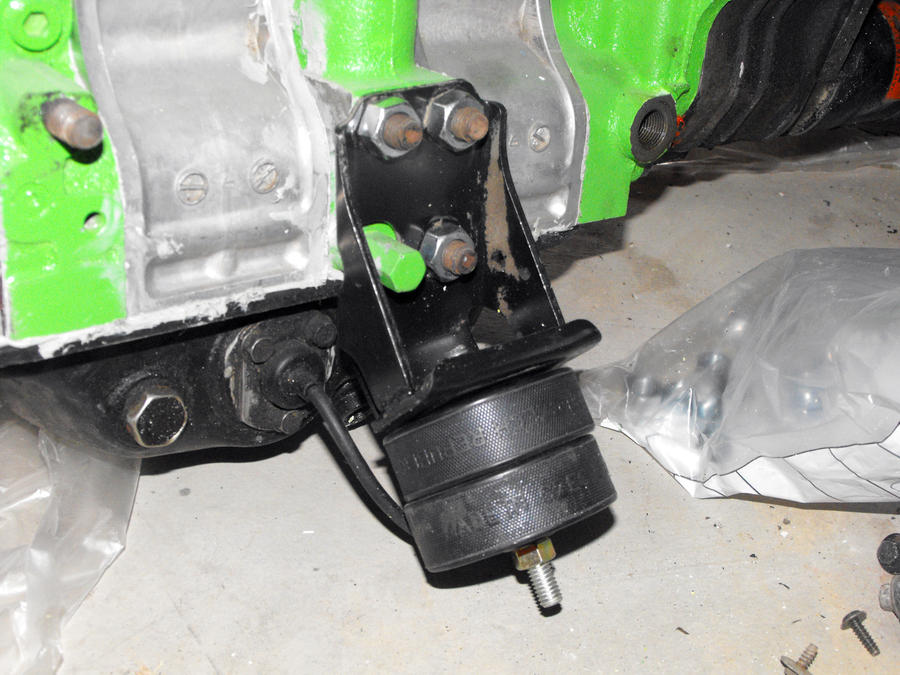

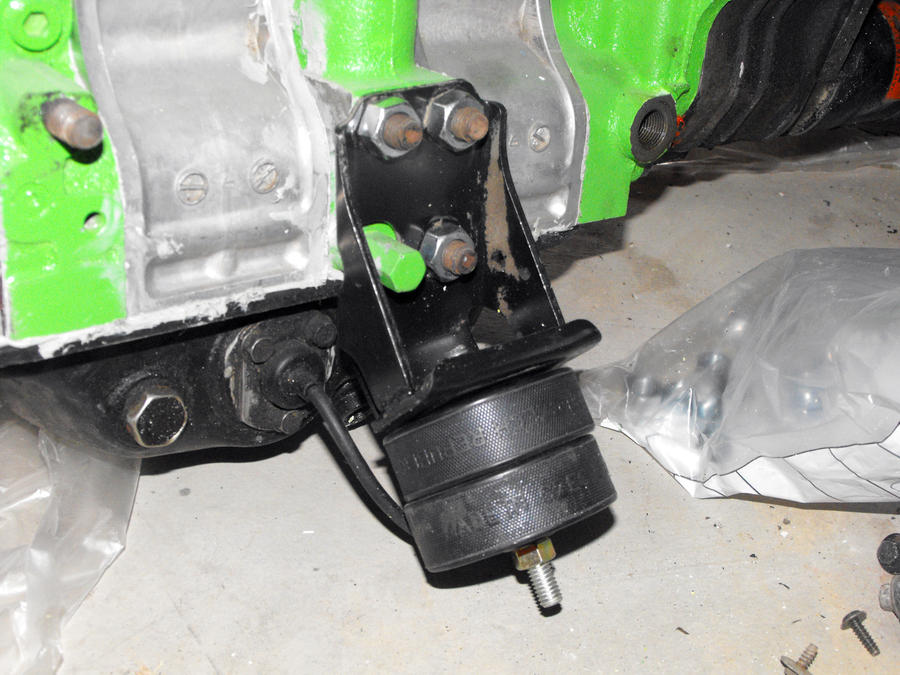

Transmission mounts:

Engine mounts:

Transmission mounts:

Engine mounts:

__________________

Originally Posted by osama tim laden

This things too low... raise it off the towhooks.

(O=O/-ROUGH WORLD-\O=O)