“When I took over the business, we were only offering custom-made connecting rods, said Saenz Lancuba. “We were leaving a huge market [stock dimension connecting rods] on the table for other companies. They [other companies] are not as good as we are. That’s when I came up with our performance series [A- and S-Model rods]. These have the same qualities as the custom-made rods with the same engineering and same structure, but the difference is we make them in large quantities and are now offering them in standard sizes. I sat down with the engineering department, and we developed the line of rods that are more affordable than the custom-made rods. We found a 4340 steel supplier in the U.S to make our custom-made and performance series rods to meet military certification. With the S-series it’s completely different, the only way to get the cost low enough was buying the 4340 in Argentina. So that is what we do with the S-series. The only difference is the 4340 steel is bought in Argentina. It only has industrial regulations and does not have military certification, and we only offer it in 4340 and not in 300M.”

Saenz Lancuba stated the business is split about evenly between race and street applications. Saenz Performance serves a wide range of customers who build high-performance as well as race engines. He added that import drag racing is a significant portion of his business. Engine builders push the envelope of performance when trying to get a competitive edge on the competition. When faced with such demands, Saenz Lancuba says, “We will see what we can do for the customer. For instance, a customer may ask if you can make a rod for 2,000 hp and 400 grams. In many cases, the closest we can get is 480 grams for 2,000 hp.

”

In addition, the company can build rods for almost any racing and high-performance engine platform. Saenz rods have proven themselves in naturally-aspirated as well as forced-induction applications. The rod designers have a difficult task and must balance between light weight and strength. Engine builders want lighter weight rods for faster acceleration, but after a certain point, you cannot go any lighter without sacrificing durability.

All the rods are meticulously engineered and exhaustively evaluated and tested for performance and reliability. Engineers use finite-element-analysis software, so the rods can maintain strength in critical areas, and material can be removed for lighter weight in non-critical areas. The beam must not stretch or deflect under enormous loads. In addition, the small and the big end sections of the rods must not come out of round. In most cases, rods do not fail under the enormous load of compression, but rather, they tend to fail under tension when an engine is over-revved. Of course, specialized premium connecting rods do have a service life. After so many miles of extreme use in racing situations, the rods become fatigued, cracked, and a failure is impending. As a result, the service life must not be exceeded.

Production Process

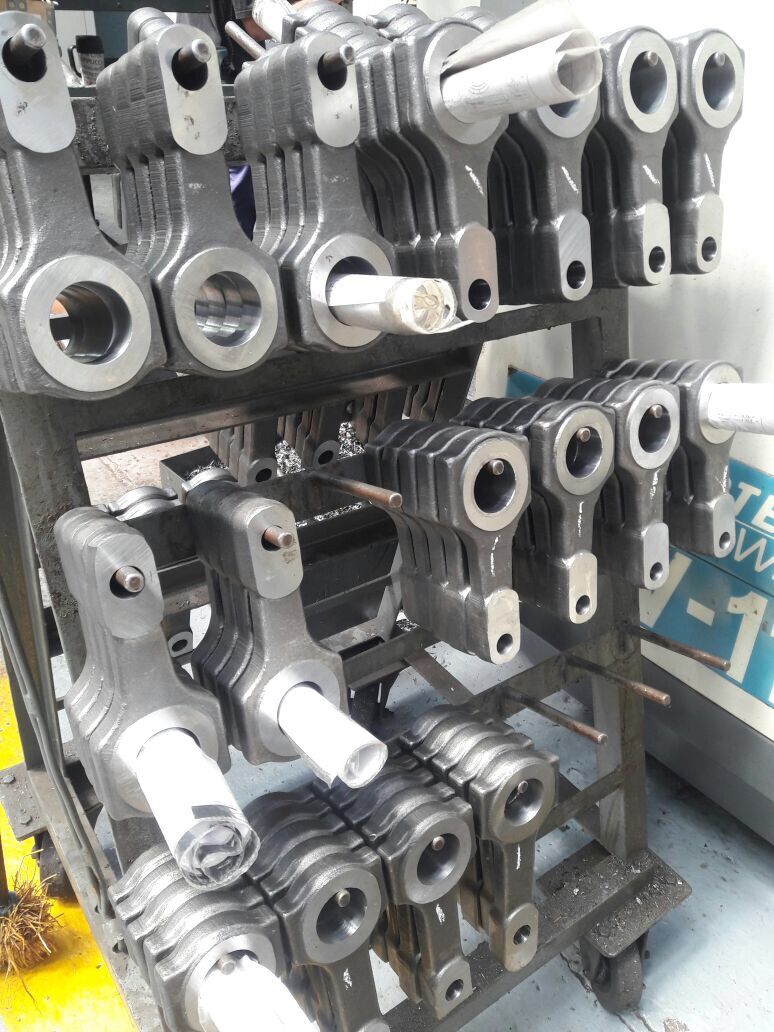

The company uses a selection of dies for forging most of the racing-engine rods to particular dimensions. During the process, Saenz seeks to obtain the best fiber orientation for the metal, but also to leave enough material for later in the machining process.

Once the rods have been initially forged, they are heat treated to strengthen the molecular structure. Then the rods are placed into a CNC mill for machining. A consistent program delivers a finely machined rod, then the big and small ends are machined out. The rods are polished in a deburring machine to remove any sharp edges and stress risers. During the shot peening process, metal shot is fired at high-velocity to create overlapping dimples providing some compression on the surface and therefore adding strength.

After shot peening has been completed, roto-finishing removes any irregularities and marks. Next, the rods are heat treated to achieve a final hardness. After completion of this step, a test (or sacrificial) rod is put through a battery of tests to ensure quality. It is inspected for core heat-treatment standards. Then the molecular structure is verified under a microscope. If the rod meets standards, it’s tagged and filed for future reference.

The guide locations are established, and the cutting zone for slicing the rod down to size is determined. Parts are fitted to the rod and then the mill grinds the rod to within .08-inch of final thickness. Next, the big end bore is machined to within .04-inch of final size and the bushings are installed.

The precision CNC machining delivers the consistency, so the weight of each rod is within one gram of each other. Rods must be balanced for race or ultra-high-performance engines because the slightest imbalance impedes power production, which could lead to a complete failure. As part of Saenz process, 80-piece rod batches are balanced to within +/- 1gram. If it’s a large order, rods must be +/- 1 percent. The big end bolt holes are resized and inspected for trueness, and then bolt stretch is measured.

As Saenz nears the end of the production process, the big and small ends are machined to final specification. The standard tolerances are very stringent at +/- 0.0008-inch, but can be as low as +/- 0.0004-inch. Next, a two-step process hones the big end bore to its final size, so heat build-up is avoided. The standard tolerance of the big end is +/- 0.00025-inch. The boring machine bores the small end to 0.0004-inch smaller than the final size. A center-to-center distance of 0.001-inch must be achieved. In addition, rods must be parallel and perpendicular within 0.001-inch in 4 inches of length. The final size of the pin end bore is then honed to a standard tolerance of +/- 0.00025-inch.

After visual inspection, Saenz uses a Brown & Sharp coordinate-measuring machine to verify that all dimensions are correct and within specifications. Next, the protective oil is applied to the rods and they are packed with a card that has dimensional and weight information. When a customer receives the rods, they are ready for prep and installation.